Location

South Korea

Sector

Transport

Bridge construction often faces challenges of time, cost, safety, and environmental disruption. GS E&C’s R&D division has responded with a fully integrated Modular Bridge System, designed to accelerate project delivery while improving quality and sustainability outcomes.

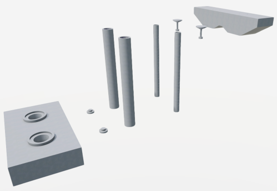

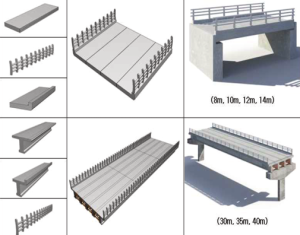

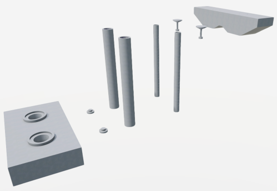

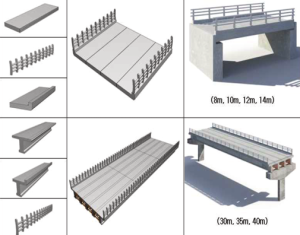

This approach replaces traditional on-site casting with precast, full-depth slabs and modular pier systems, which are manufactured off-site under controlled conditions and installed rapidly with minimal disruption. The system includes high-performance materials like UHPC (Ultra-High-Performance Concrete) and GFRP (Glass Fiber Reinforced Polymer), delivering greater strength and durability at lower weight.

A key innovation is the web-based integration platform, which supports digital planning, standardisation of components, and automation. Module sizes are standardised (e.g. 8m–14m slabs; 30m–50m girders), allowing design repeatability, faster approvals, and improved supply chain efficiency.

The benefits are clear: faster installation, reduced costs, minimal environmental impact, and easier long-term maintenance. This makes modular bridge technology particularly effective for urban areas, disaster recovery, and time-critical infrastructure projects.

GS E&C’s modular system reflects its commitment to human-centred, future-ready solutions, offering scalable technologies that redefine how we build bridges—more efficiently, safely, and sustainably.