Tunnel Boring Machines (TBM) are increasingly used to deliver safe, low-impact underground infrastructure. Traditionally, Korea’s TBM tunnel linings have relied on reinforced concrete (RC) segments with steel rebar cages—a process that’s labour-intensive and costly. Recognising the need for a more efficient solution, GS E&C is advancing the use of Steel Fiber Reinforced Concrete (SFRC) and hybrid segment designs, aligning with international best practices.

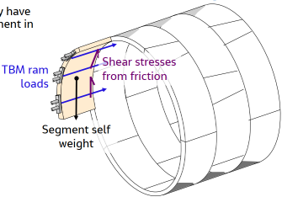

SFRC uses dispersed steel fibers within the concrete mix, eliminating the need for rebar while maintaining strength and flexibility. This innovation offers cost savings, improved crack resistance, and simplified handling and production. It also enhances performance under key TBM conditions such as ram loads, segment self-weight, and shear stresses.

GS E&C’s optimisation process includes segment design modelling, joint capacity analysis, and manufacturing alignment. Technical support is also provided through capacity-building and production guidelines covering de-moulding, stacking, and transportation.

With plans to adopt SFRC in Korea (pending specification updates), GS E&C is helping drive more efficient, scalable, and durable tunnelling solutions. This reinforces the company’s commitment to future-ready, human-centred infrastructure, meeting modern transport demands with smarter materials and processes.